3D Data

Unlock the Power of Interoperability and Precision in Your CNC Software

Spatial Team | 22-01-2024

CNC routing software is an indispensable tool that gives manufacturers new levels of precision and speed in product development and on the production floor that are essential in today’s highly ...

Categories

All Posts 3D Modeling 3D Software Development Kits Additive Manufacturing 3D InterOp 3D Interoperability CGM Modeler 3D ACIS Manufacturing & Fabrication 3D Data 3D Visualization Building Information Modeling (BIM) 3D Precise Mesh Hybrid Modeling 3D Printing CGM Polyhedra Cloud & Mobile HOOPS Visualize HiddenBodyRemoval Meshing insider spatial

7 min read

Tips to Your Elevate CNC Routing Software | Spatial

Author:

Spatial Team

CNC routing software is an indispensable tool that gives manufacturers new levels of precision and speed in product ...

4 min read

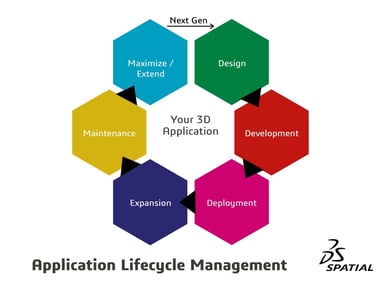

How to Reduce Development Time and Maximize Revenue During Application Lifecycle Management

Author:

Spatial Team

When you hear the term, Application Lifecycle Management (ALM), you likely think about the process that a software ...

2 min read

What is a WRL File?

Author:

Spatial Team

WRL files are an extension of the Virtual Reality Modeling Language (VRML) format . VRML file types enable browser ...

3 min read

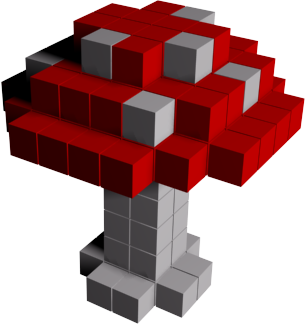

The Main Benefits and Disadvantages of Voxel Modeling

Author:

Spatial Team

Voxels are to 3D what pixels are to 2D. Firstly -- let’s examine what pixels actually are. Everything you see on your ...

2 min read

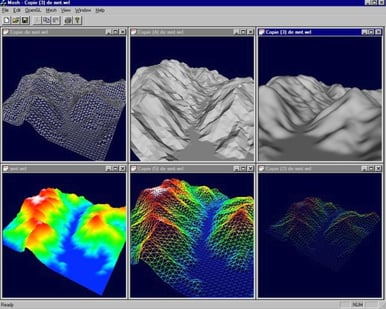

The Main Benefits and Disadvantages of Point-Cloud Modeling

Author:

Spatial Team

Point-cloud modeling is typically used in the process of 3D scanning objects. Rather than defining surfaces through ...

2 min read

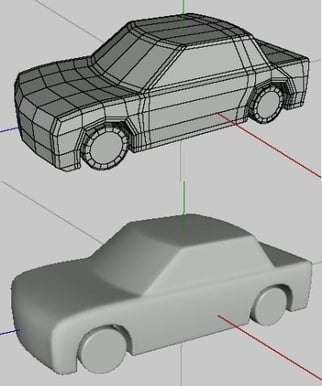

The Main Benefits and Disadvantages of Polygonal Modeling

Author:

Spatial Team

Polygonal (or polyhedral) modeling is the most common type of modeling for video games and animation studios. This type ...

9 min read

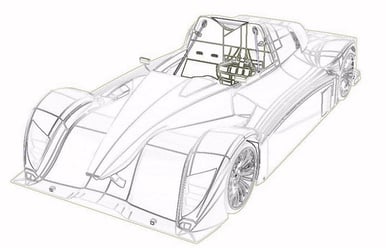

13 Key Applications of CFD Simulation and Modeling

Author:

Spatial Team

Computational fluid dynamics (CFD) is a science that uses data structures to solve issues of fluid flow -- like ...

2 min read

The Main Benefits and Disadvantages of BRep Modeling

Author:

Spatial Team

BRep modeling, or Boundary Representation modeling, is, in CAD applications, the most common type of modeling. BRep is ...

5 min read

What is FEA (Finite Element Analysis) in CAD?

Author:

Spatial Team

IN THIS ARTICLE: What is FEA (Finite Element Analysis) Principles of Finite Element Analysis and Simulation Software A ...