3D printing technology has driven amazing advances in additive manufacturing. Product developers, manufacturers, and even apartment developers have made impressive strides in their industries because of modern 3D printing solutions, even using carbon fiber in 3D printing.

3D printing is fueling a new era of innovation that’s seemingly encompassing everything from medical breakthroughs to lucrative side hustles. Even the use of carbon fiber 3D printing technology is becoming increasingly common.

In this article, we’ll explore the growing world of 3D printing with carbon fiber and share everything you need to know when determining if this technology is right for you.

Understanding the Material: What is Carbon Fiber?

Carbon fiber is favored by many manufacturers for its high-performance, low-density, and thermal properties.

It consists of thin strands of tightly woven carbon atoms and is predominantly used by manufacturers where a product’s strength, weight, and/or resistance to heat is of utmost importance.

Industries That Use Carbon Fiber for Manufacturing

Carbon fiber’s impressive strength-to-weight ratio and ability to withstand extreme temperatures has positioned it as a material favored by several industries. A few of which are:

Aviation

Airplane hulls, fuselage, body panels, bumpers, and other parts are often made from carbon fiber. Carbon fiber can help reduce a plane’s weight by up to 20 percent.

High-Performance Race Cars

Racing teams need cars made with lightweight yet extremely strong materials. This is why carbon fiber is often the preferred choice.

Sporting Goods

The durability, low weight, and ruggedness of carbon fiber make it a desirable material for manufacturing sporting goods, such as bikes, fishing equipment, canoes, skis, snowboards, or tennis rackets.

Medical Research

In addition to its strength, durability, and lightweight nature, carbon fiber has excellent biocompatibility properties ideal for prosthetics, orthotics, dental implants, and other ground-breaking medical research.

Assembly Line Robots

Strong, heat-resistant tools that are also lightweight and made from carbon fiber are frequently used in assembly-line robotics.

Pros and Cons of Using Carbon Fiber for Manufacturing

| Pros |

Cons |

|

|

|

|

|

|

|

|

|

|

Why Carbon Fiber for 3D Printing?

With so many options for 3D printing composites and filaments, the question arises, why carbon fiber for 3D printing? Why not stick to time-tested materials like Acrylonitrile Butadiene Styrene (ABS) or Polylactic Acid (PLA)? The answer lies in the unique properties that carbon fiber brings to the table.

In short, carbon fiber is stronger, more durable, weighs less, and performs better in precision processes than other 3D printing materials.

For instance, Acrylonitrile Butadiene Styrene (ABS) isn't suitable for lightweight products because it’s plain heavier than carbon fiber. Additionally, ABS will expand when exposed to high temperatures and isn’t as biocompatible as carbon fiber, making it a poor choice for medical and aviation applications.

Similar reasons apply when comparing carbon fiber to Polylactic Acid (PLA) as well.

Plus, 3D-printed carbon fiber offers a faster, easier way to simplify the traditionally complex carbon fiber manufacturing process.

Products commonly manufactured using 3D carbon fiber printing technologies include:

- Tooling optimization for ergonomic-friendly parts

- Functional prototyping

- Bike parts

- Car parts

What is 3D Printing of Carbon Fiber?

Simply put, carbon fiber 3D printing is the use of 3D printing technology where carbon fiber is the primary printing material. However, as with all advanced printing technologies, the reality of carbon fiber 3D printing is much more complex than that.

There are different types of 3D printing methods for carbon fiber, and even more types of carbon fiber matrices manufacturers can select from.

Common 3D Carbon Fiber Print Methods

Three of the most utilized printing methods carbon fiber 3D print methods include:

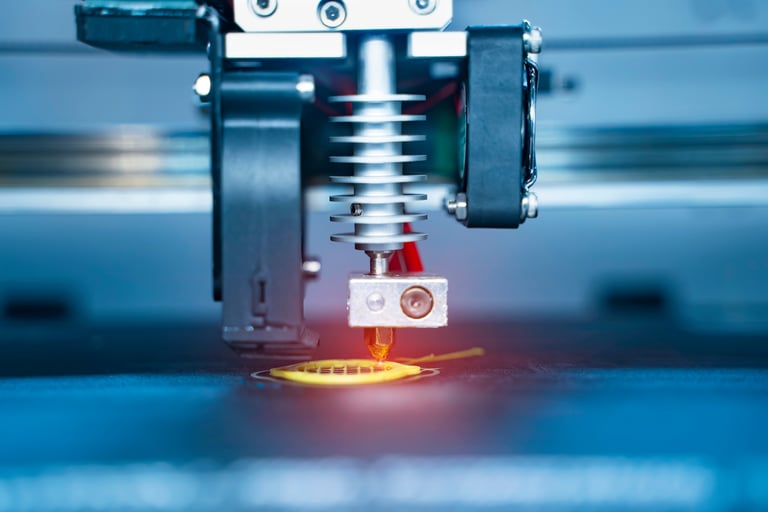

- Fused Deposition Modeling (FDM). In FDM printing, a carbon fiber-infused filament is melted and extruded through a steel-hardened nozzle. Using uploaded digital design files as its guide, the FDM printer renders 3D objects that are lightweight, strong, and corrosion-resistant.

- Continuous Filament Fabrication (CFF). CFF methods rely on two nozzles to build a design rather than the single nozzle used in FDM applications. One nozzle extrudes a carbon filament, and the other extrudes a thermoplastic filament.

- Selective Laser Sintering (SLS). In SLS 3D print methods, high-powered lasers are used to fuse powdered plastic material together, one layer at a time, into 3D shapes.

Next-Level Product Design Needs the Right 3D Modeling Technology

Ready to shorten TTM and advance designer innovations?

Learn HowMaterials Used for Printing Carbon Fiber with 3D Methods

Fused Deposition Method

In FDM applications, the most common carbon fiber filaments engineers use are thermoplastic composites augmented with chopped carbon fibers. Examples of thermoplastics it can be infused with include:

- PLA

- PEEK

- PTG

- Nylon

Continuous Filament Fabrication

CFF methods utilize filaments augmented with continuous carbon fibers, rather than chopped fibers typical in FDM applications. This produces items with greater tensile strength than ones generated with chopped fiber filaments.

Selective Laser Sintering

For SLS printing of carbon fiber items, the rendering medium is a polymer powder infused with carbon fiber. This is an ideal option when surface finishing and complex geometries are a top priority.

Other factors affecting what carbon fiber print method and materials are used can include budget, product use, development timeline, material availability, or other unique specifications.

Comparison of FDM, CFF, and SLS Methods in 3D Carbon Print Applications

| FDM |

CFF |

SLS |

|

| Material |

Thermoplastic filaments infused with chopped carbon fiber |

Standard filament core and continuous carbon fiber filament |

Polymer powder infused with carbon fiber |

| Mechanical Properties |

Good strength in the direction of the extrusion but weaker strength between layers |

Stronger than FDM renderings due to the continuous carbon fiber strands. |

Creates isotropic properties that generate similar strength in all directions. |

| Surface Finish |

Low-quality surface finish |

Low-quality surface finish |

High surface finish quality, handles complex geometries |

| Cost and Speed |

Fastest, most cost-effective method |

Similar speed as FDM, higher material costs |

Highest cost for material and printing instruments, comparable speed to FDM and CFF |

| Ideal Applications |

Prototypes, jigs, tooling, large parts |

Structural components requiring high strength and stiffness |

Use to create products with high-complex geometries and mechanical specifications |

Unlock Your 3D Carbon Printing Potential with Spatial

At Spatial, we help engineers and developers harness the potential and power of 3D technologies with top-quality 3D modeling SDKs—especially when it comes to additive manufacturing.

It's time to optimize your workflows and ensure seamless translation from models to machine code. You can trust Spatial to maintain data integrity throughout the 3D model’s lifecycle.

To learn more about how your team can reach new potentials by leveraging the power of carbon 3D printing, consult with our experts.