Hybrid manufacturing is revolutionizing both manufacturing and product design—thanks to the rapid evolution of manufacturing technologies. But it can be difficult for manufacturers, product designers, and engineering firms to keep up.

3D printing and additive manufacturing, combined with new subtractive manufacturing technologies and more sophisticated software and hardware, have pressured manufacturers to continually upgrade their equipment and processes.

Manufacturers are under pressure to deliver products faster, cheaper, and better—creating a need to automate and connect design and manufacturing processes more and more.

Hybrid manufacturing is one such example of this convergence, with hybrid manufacturing technologies making it possible to design and manufacture products requiring both additive and subtractive processes. The added bonus? You’re able to use the same software suite and machine.

However, with this streamlined manufacturing process comes increased reliance on data accuracy and visibility, making it critical to have integrated software that can produce highly detailed and accurate models. You should also be able to share the relevant CAD data across design and manufacturing teams to reduce the risk of errors in the manufacturing process.

In this article, we’ll define what hybrid manufacturing is, go over its benefits over traditional manufacturing processes, look at some hybrid manufacturing examples, and explore the importance of clean and accurate CAD data in hybrid manufacturing.

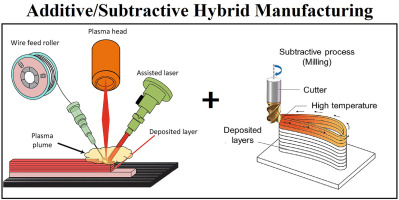

Hybrid manufacturing is a manufacturing process that combines both additive manufacturing, also known as 3D printing or AM, with subtractive processes, such as CNC machining (milling, grinding, rolling, drilling, and turning), usually on the same machine.

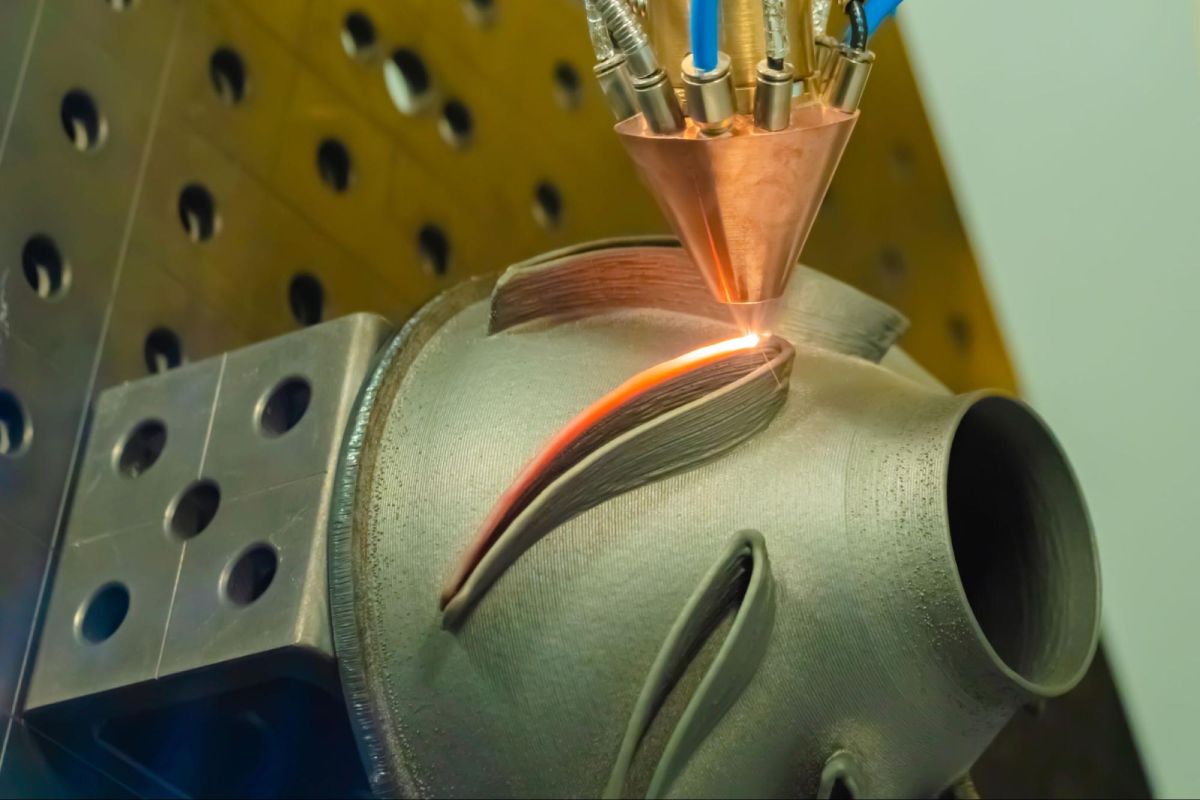

Hybrid machines usually consist of a machining tool, such as a lathe, which also has a directed energy deposition (DED) head to deposit wire or metal powder. Other manufacturing systems may combine machining with powder-bed fusion (PBF) or material extrusion. These machines are called one-step hybrid machines because they can perform subtractive and additive manufacturing in a single process.

Hybrid systems and one-step hybrid machines offer many advantages compared to traditional manufacturing processes.

Hybrid manufacturing allows the fabrication of products to be done more efficiently, quickly, and with fewer machines by streamlining the design and manufacturing process in a unified environment. Because a 3D printed part never has to leave the build envelope, there’s a smaller chance of errors.

Hybrid manufacturing creates more freedom in design and allows for more intricate and complicated parts to be created much more easily by taking advantage of the speed of 3D printing and the flexibility of subtractive detail work. Sometimes, parts also benefit from the ability to alternate machining and printing to finish detailed internal work, such as cooling channels in injection molds.

(image source: Science Direct, 2022)

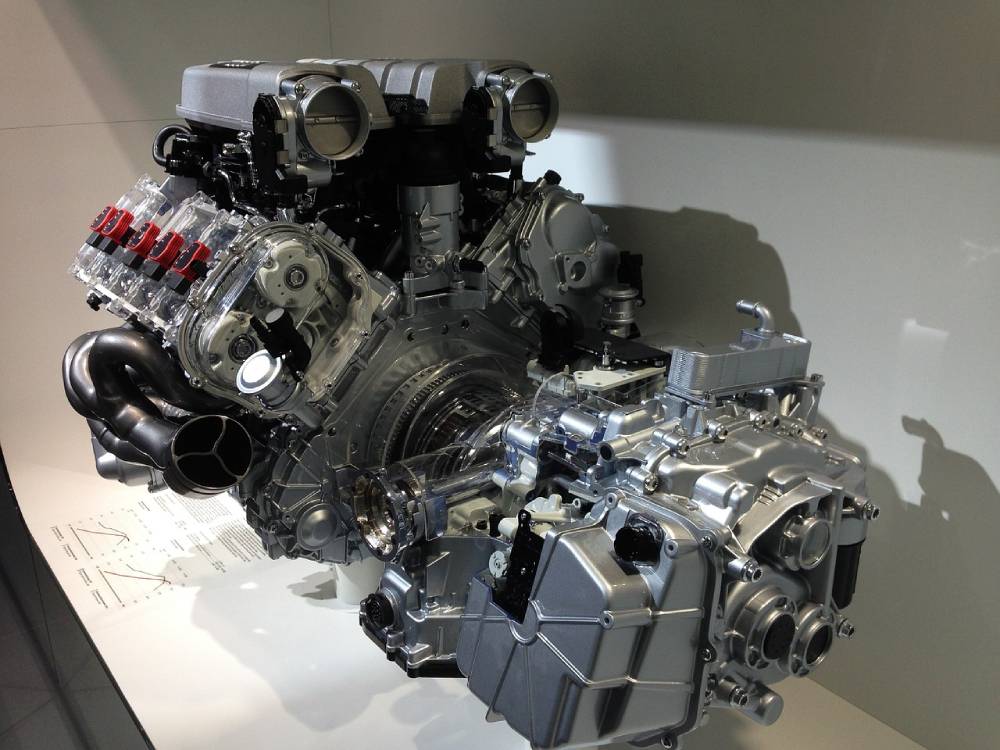

Hybrid manufacturing is a relatively young technology, but its use is growing rapidly in the automotive and aerospace industries. One common example of hybrid manufacturing is when you 3D print parts using metal deposition with a metal powder, followed by post-processing subtractive machining. This machining has metal milling and polishing machine tools to smooth the surface of the part.

Another example, in reverse, is subtractive machining being used to cut or mill a form from a piece of metal, followed by additive manufacturing that adds thin coats on this base to finalize the part.

Hybrid manufacturing opens up the possibility of combining materials during manufacturing. For example, a part may require heat or stress resistance in one area but not throughout the whole part. You’re able to save money by using cheaper materials to print most of the part.

Hybrid manufacturing is well-suited to many industries, but a few examples include:

Types of hybrid machines used by these industries include off-the-shelf machines that come with both AM and subtractive capabilities, as well as re-designed subtractive machines that have had AM capabilities added.

Although there are many benefits to hybrid manufacturing, as with any new technology, you need to be careful as you develop new workflow processes. In the process of moving from design to manufacture, CAD data exchange processes may create errors at the file level, as a file is moved between programs or modeling types.

Team members may also introduce errors if they misinterpret data in hard-to-decipher documentation.

It is more crucial than ever, then, that you pay attention to data cleanliness best practices and strive to make clean models. This helps ensure smooth transitions between design, 3D printing, and subtractive manufacturing.

A model can be called clean if it is easily understood by all team members and has precise and accurate data. You also need the associated documentation to interpret the data. You must strictly follow industry and internal standards, use tools to ensure that standards are followed, and keep data integrity intact.

To catch the attention of new customers and offer more value to your existing customers, you need a competitive advantage that puts you at the leading edge of manufacturing.

Learn how 3D modeling is transforming the manufacturing landscape with these blogs: |

To add hybrid manufacturing to your workflow, you need software that can take different types of models with different levels of complexity, and make them compatible with hybrid manufacturing equipment.

This is where hybrid modeling comes in. Spatial’s CGM Modeler SDK empowers 3D software developers to build hybrid modeling easily into their applications. You’re able to go from importing CAD data from designs to modifying models based on machining equipment capabilities.

With Spatial's hybrid modeling SDKs, you can offer model preparation capabilities for additive and subtractive processes in one application. With these, you’re able to expand the scope of your applications by easily building pre-, and post-processing tools into your hybrid manufacturing platforms, including:

Hybrid manufacturing reduces waste, saves time and money, and provides incredible flexibility for complex, customized parts. There will be no industry untouched by hybrid manufacturing in the future—even just based on its financial benefits.

However, you’re going to need software with advanced features that’s purpose-built for hybrid manufacturing and prevents data integrity issues. Without integrated software solutions that combine additive and subtractive workflows, manufacturing processes will remain in the past.

Step into the future with hybrid manufacturing. Contact us today.

ACIS, 3DScript and SAT are registered trademarks of Spatial Corp.

No Comments Yet

Let us know what you think