Sheet metal, a linchpin in modern manufacturing, has a storied history that traces back to the Industrial Revolution. As industries evolved, so did the tools and techniques shaping them. In today's digital age, advanced software and automated solutions are revolutionizing how sheet metal designs are conceptualized and executed.

As efficiency, resource management, and energy conservation become increasingly paramount to manufacturers' bottom line, leveraging the newest technologies in sheet metal design will help companies get more out of their resources than ever before.

“Taking advantage of what technology has to offer gives manufacturers and engineers an easier, faster, and more efficient way to design and customize products with sheet metal. Today’s software solutions go beyond traditional CAD capabilities; they increase design visibility, reduce time engineers spend managing their data, and help improve management of material usage.”

Craig Dennis, NAM Technical Director, Spatial

In this article, we’re digging into the world of sheet metal manufacturing and how software is guiding this industry toward the future.

The Role of CAD in Sheet Metal Design

For decades, the fabrication industry primarily relied on 2D drawings to communicate design intent. These two-dimensional geometries, while familiar and comfortable for many designers, had limitations. They were paper-based, took forever to build out, were challenging to replicate or edit, and didn’t provide real-life visualizations.

These classic renderings served their purpose quite well - before the digital revolution took hold, that is. Once technology innovations were made and industrial design demands grew, so did the need for a more advanced design methodology.

From 2D Drawings to 3D Visualization

This led us to the world of Computer-Aided Design (CAD). CAD added a whole new dimension to product development. The transition from 2D to 3D CAD workflows marked a significant shift in how designs were conceptualized across numerous manufacturing industries, including sheet metal design.

3D CAD not only offers a more detailed visualization but also ensures greater accuracy, thereby reducing the chances of errors and rework.

Sheet Metal CAD Software: Enhancing Precision and Collaboration

3D sheet metal design, facilitated by CAD, has brought about a level of precision that was previously unattainable with traditional 2D drawings. This enhanced accuracy means that engineers can quickly create detailed sheet metal models, identifying potential bottlenecks or issues early in the design process.

Moreover, the 3D approach has bridged the communication gap that often existed between different stakeholders. Whether it's contractors, project managers, designers, or fabricators, everyone can now have a clearer understanding of the design intent.

Plus, any changes made in the 3D model are instantly reflected in associated drafts, thanks to the parametric capabilities of modern CAD software.

Explore other industries where Spatial’s expertise and 3D modeling is driving innovation:

Driving Efficiency in Modern Manufacturing

The transformative impact of CAD on sheet metal design isn't just limited to visualization and communication. It's also about efficiency. With the adoption of 3D workflows, many opportunities have opened up for the fabrication industry.

For instance, design automation with 3D CAD models can significantly boost productivity. Manufacturers can automatically generate client-specific 3D product models, drawings, and documentation. This level of automation, combined with the precision of 3D designs, has led to reduced lead times, giving companies a competitive edge in the market.

Modern Challenges in Sheet Metal Design

However, we’re not trying to say CAD eliminates every challenge sheet metal designers face. There are still much-needed improvements that need to be made and plenty of challenges to address. A few of these examples are detailed below.

Balancing Efficiency with Flexibility

CAD brought in new standardizations that enabled many solutions to be carried out at scale, allowing for efficient and cost-effective production. As efficient as these standardizations can be, they don’t address non-standard or custom applications.

This is because customization requires flexibility in the production process to cater to specific client or project demands. Balancing these two can be challenging, as optimizing for one can compromise the other.

Complexity in Design and Production

Manufacturers are often limited in their ability to accept customized orders. This is because customizations often come with unique design specifications. This can introduce complexity in the design and production processes and may not be financially feasible to carry out.

Complex solutions may even require specialized tools, dies, or machinery setups, which can disrupt the streamlined processes set for standardized products as well as being more costly to execute.

Material Wastage

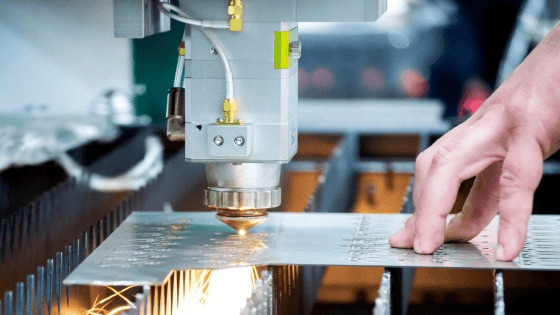

Sheet metal, depending on the grade, type, and thickness of the sheet, can be expensive. Wastage directly translates to increased material costs, which can impact the overall profitability of a project. As costs of resources rise and the pressure to limit waste production increases, manufacturing companies need more effective ways to lower their sheet metal wastage levels.

Sheet metal waste during the production process can reach 15% or more. Reasons for increased waste in production of items made from sheet metal often include poor cutting plans, incorrect cuts and tooling misalignments, and poor resource management.

Interoperability and Collaborations

Interoperability poses a significant challenge in sheet metal production, especially with teams using different CAD files and programs. Seamlessly integrating data across these systems is crucial to ensure accurate designs and reduce errors. Misinterpretation or data loss during format conversion can lead to costly mistakes and production delays.

Collaboration is further complicated by these interoperability issues. When design teams, manufacturers, and other stakeholders cannot easily share and access consistent design data, it hampers effective communication. This lack of cohesive collaboration can result in misaligned production goals and inefficiencies in the manufacturing process.

Data Management

Efficient data management in sheet metal design is paramount. With the transition from 2D to 3D CAD systems and the need for compatibility across various software, managing large-scale models and ensuring smooth data transitions become challenging. Discrepancies in data or using outdated design versions can lead to production errors.

Furthermore, the balance between standardization and customization introduces variability in design data. Managing this diverse data, especially when integrating custom designs from various sources, requires meticulous oversight. Any oversight can result in increased material wastage and production inefficiencies.

CGM Modeler: A Game-Changer for Sheet Metal Design Software

Unparalleled Precision in Design

The CGM Modeler stands out with its state-of-the-art design tools, setting a new benchmark in the realm of sheet metal production. Its capabilities are especially evident when handling intricate geometries, ensuring that designs are both accurate and practical for real-world applications. With CGM Modeler, you can tap into:

- Reduced production errors: Minimized discrepancies between design and the final product.

- Consistent product quality: Uniformity in design leads to consistent output.

- Optimized material usage: Precision ensures efficient material utilization, reducing wastage.

- Faster turnaround: Accurate designs streamline the production process, reducing lead times.

From Conceptualization to Production

CGM Modeler bridges the gap between conceptualization and actual manufacturing. Its advanced simulation capabilities allow manufacturers to visualize real-world production scenarios, previewing the end result.

This foresight is invaluable, enabling early detection of potential bottlenecks or issues. By ensuring that the design aligns perfectly with production capabilities, CGM Modeler streamlines the entire production process, ensuring efficient material and resource utilization and ultimately delivering a product that meets the highest standards of quality and precision.

3D InterOp Suite: Bridging Gaps in Sheet Metal Fabrication Software

In the diverse world of sheet metal design, professionals often grapple with multiple CAD systems. Each system, with its unique format and features, can introduce data incompatibility issues. These disparities not only hinder efficient design but can also disrupt the seamless transition to production, leading to costly errors and delays.

Enter the 3D InterOp Suite. This powerful tool ensures accurate data translation between varying CAD systems, preserving the integrity of even the most intricate designs. Whether you're dealing with complex geometries or custom specifications, 3D InterOp maintains design fidelity, eliminating the headaches of format mismatches.

But it's not just about translation; it's about collaboration. By fostering seamless integration, 3D InterOp enhances collaboration among design teams, manufacturers, and other stakeholders. This unified approach drastically reduces errors, minimizes rework, and ensures timely production.

Embracing the Future of Sheet Metal Production

The advancements in sheet metal design software, epitomized by tools like the CGM Modeler and the 3D InterOp Suite, are reshaping the manufacturing landscape. As challenges mount and the demand for precision and efficiency grows, it's imperative for businesses to stay ahead of the curve.

Spatial's cutting-edge solutions offer the promise of streamlined operations, reduced errors, and enhanced collaboration. Ready to move your production processes forward?

Consult with Spatial today and elevate your sheet metal production to new heights.