In the past, 3D printing was used mainly by major manufacturers that could afford expensive printers and materials. Over the years, 3D printing technology has evolved and become more affordable, making it a viable option for a wide variety of industries. Medical professionals, in particular, are beginning to use 3D printing to improve their practices and offer more customized and affordable healthcare options for their patients.

Healthcare is one industry in which 3D printing has made a lasting impact. In 2018, the medical 3D printing market was valued at $973 million and is expected to grow to almost $3.7 billion by 2026. Medical applications for 3D printing are vast and will likely change the industry forever. Here are some of the most significant applications of 3D printing in the medical field.

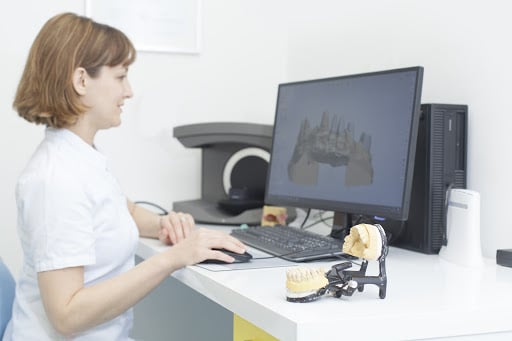

Medical Industry 3D Printing Software for Detailed Visualizations

The medical industry uses 3D printing to create critical items, such as medical equipment, devices, and prosthetics. In order to print, objects first need to be designed using specialized 3D software. Once you have a 3D model, you can use the software as a viewer to see detailed, three-dimensional images of customized equipment and patient scans.

When working on customized equipment, you and your team can look over and collaborate on the designs to ensure that they’re perfect for your desired application before spending any real-time, money, or material on printing.

Some medical professionals use 3D software even if they don’t plan on printing. It’s a helpful way to visualize projects and scans to develop a strategy for upcoming medical procedures.

There’s a wide variety of 3D modeling software on the market, so there’s no one-size-fits-all solution and you need to know what you need most.

Do you only need to print, or are you looking for a software that offers more detailed visuals? Perhaps you need a combination of both? There’s no right answer, so it’s important to take your time and weigh the pros and cons of each software to determine which one is right for your practice.

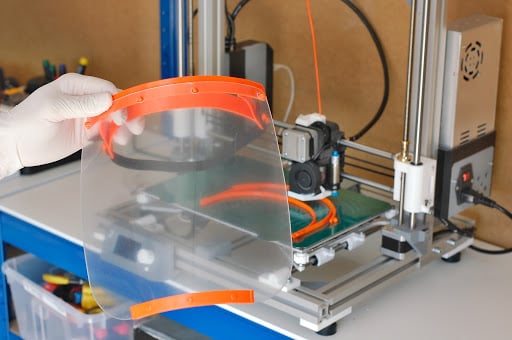

Create Custom 3D-Printed Tools for Medical Industry

Medical devices are designed to be as versatile as possible, but sometimes it’s helpful to have something that’s a bit more customized. Specially ordering the tools you need can be expensive and take a long time to arrive. With 3D printing, you can create custom tools in a matter of hours, not weeks - and you can create specialized tools for any job.

Healthcare professionals create customized surgery tools based on patient CT scans - tools that have been perfectly adapted for each patient and procedure. By knowing that the tool will fit the unique situation, doctors can be more prepared and efficient with their work.

Studies have shown that having 3D printers in the medical field can reduce operation times and increase surgical accuracy, especially in the oral and maxillofacial fields.

prostheses Tailor-Made for Patients

Prostheses made using traditional manufacturing methods are expensive and not necessarily adapted to a patient’s unique morphology. If a patient does need a custom prosthesis, the costs can skyrocket, and it would take some time for the order to be fulfilled.

Prostheses, by definition, need to be custom-made for the patient. After all, no two people are exactly alike or have the exact same injuries. Doctors can use 3D modeling software to help create detailed, three-dimensional images of prostheses that they can collaborate with each other - and perhaps more importantly, with the patient - to ensure a proper fit.

Then, using 3D printing, they can create customized prostheses that are perfectly suited to fit their patients’ exact needs in a timely, cost-effective manner.

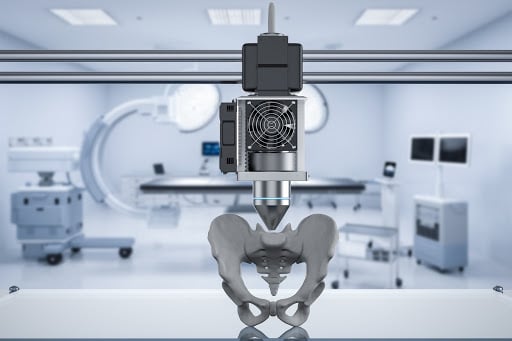

Bone and Joint Reconstruction

Just like prostheses, you can also use medical 3D printing to help with bone and joint reconstruction. Instead of using a one-size-fits-all implant (that often doesn’t “fit all”), you can use additive manufacturing to create customized implants.

In addition to bone reconstruction, healthcare providers are also starting to 3D print synthetic cartilage that can be used to rebuild joints and other body parts. Here are just a few of the major applications for which 3D printing can be used:

- Jaw reconstruction

- Hip replacements

- Knee replacements

- Breast reconstruction

- Facial reconstruction

This list is by no means exhaustive. The possibilities for Medical applications for 3D printing are endless and new, innovative solutions are being developed all the time.

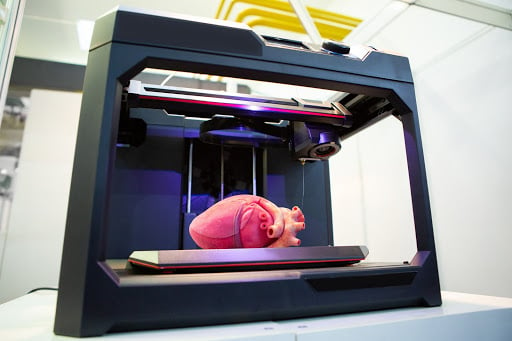

Bioprinting Artificial Organs and Tissue

Thanks to a process called bioprinting, medical 3D printers are now able to print functional tissue. Rather than using metal or plastic, bioprinters can create models with living cells. Soon, 3D printers in the medical field will be able to create tissue to help with skin grafting and reconstructive surgery. Labs are also starting to experiment with printing liver and intestinal tissue to help manage certain diseases.

In a more miraculous form of bioprinting, experts are using 3D printing to create functional human organs. So far, researchers have been able to replicate a working lung and an artificial heart. It won’t be long before patients won’t need to wait on transplant lists or spend inordinate amounts of money to get the organs they need.

3D Medical Printing for Dental Applications

Dentists and orthodontists need customized solutions to help their patients, as no two mouths are the same.

Instead of taking the time to make molds and create custom apparatuses, dentists can now 3D print braces, crowns, dentures, or anything else they might need based on patient X-ray and CT images.

The entire process - from the scan to creating the 3D model to pressing the print button - can be done by a single person, not a team, which can save time, labor, and money. Those savings can then potentially be passed along to the patients for more affordable dental care.

Medical Training for Complicated Procedures

Medical professionals can look at charts or scans to help plan complicated or rare procedures, but they don’t always get much real-world practice beforehand. With medical 3D printing, now they can.

In 2016, surgeons in Ireland were tasked with performing an intricate kidney transplant from a father to his two-year-old daughter. They created 3D-printed models of the child’s torso and the adult kidney, so the doctors could practice the complicated surgery and develop a strategy ahead of time. The surgery was a success.

Using 3D printed organs and models as a means of practice can give surgeons the knowledge and experience they need to undertake even the most difficult surgeries. Using this training, doctors will be more confident in surgery and have a greater chance of success.

How to Get Started with 3D Medical Printing

As time goes on and 3D printing becomes even more accessible, medical professionals will find even more innovative medical applications for 3D printing to deliver customized solutions for patients.

If you’re a designer or a software developer looking to get into 3D modeling and printing, it’s easier to get started than you might think. Start by downloading a 3D modeling software to learn the basics.

If you can’t find the perfect 3D Printing software for your needs, you can build it using 3D software components. Spatial, with their 3D experts and technology, have helped numerous software developers do just that!

With the incredible things happening with 3D printing in the medical industry, including detailed 3D models, customized tools, prosthetics, bone reconstruction, and synthetic organs, there’s no doubt that this is the future of healthcare.