Modern 3D printing medical advances offer real, practical medical solutions that include living tissue production, personalized anatomic models, and low-cost surgical equipment manufacturing.

The industry is moving fast, too. The global market for 3D printed medical devices is expected to reach $2.21 billion by 2023.

These game-changing applications are worth getting excited about as they represent a new era of healthcare management - anatomy, structures, and devices can be custom-fitted to each patient based on his or her unique physiology.

Among these applications, we’re seeing a few noteworthy trends stand out from the pack.

1. Tissue Fabrication

A broad area of study for 3D medical printing is tissue fabrication—a.k.a. “3D bioprinting.” Researchers combine living cell tissue with biopolymer gels to create “bio-inks” that are fed into the 3D printer and are, with the help of simulation models, assembled layer by layer into the desired design.

This (relatively) simple idea opens up a world of possibilities for 3D printing medical breakthroughs. Researchers have more ways than ever to reproduce living tissue in vitro and explore their characteristics.

Cancer tumors can be studied in depth to monitor progression, disease cells can be tested to better understand pathologies, and blood vessels can be reproduced and studied to better understand complex cardiac anatomy.

And these applications are just the tip of the iceberg. Researchers are taking it a step farther to study how 3D printing technology can be combined with photopolymerization to enable non-invasive bioprinting of tissue constructs.

2. Organ Printing

One of the most exciting applications of 3D human tissue printing is full-fledged organ replacement. There are big implications for this type of 3D printing medical breakthrough, including the elimination of organ shortages for transplants and much better outcomes in organ transplantation. (As of February 2020, the U.S. alone has over 111,000 people waiting for life-saving organ transplants.)

And while researchers have not yet been able to reproduce full organs for transplantation, they’re making progress. Scientists have recreated small amounts of cardiac heart tissue in lab settings that match the physiological characteristics of the donor patient, an important step toward re-creating a full 3D-printed human heart.

This is just one example of how 3D printing software helps move medical research to the point where we can create fully customized, implantable medical structures.

3. PPE Production

In light of the 2020 coronavirus pandemic, personal protective equipment (PPE) has become a hot topic. It’s well-known that manufacturers are struggling to keep up with the global demand for PPE, and with lives on the line, it stands to reason that this would be a big area of focus for 3D printing. Several new 3D-printed PPE designs have entered the market in response to the pandemic.

All PPE designs must follow the U.S. Food and Drug Administration (FDA) guidelines on 3D printing personal protective equipment. These guidelines have been updated for the coronavirus pandemic, noting a variety of potential applications:

- Face masks

- Goggles

- Ventilators

- Gowns

- Gloves

Of course, the FDA notes several challenges as well: Not all 3D printed PPE will provide the same level of protection as traditionally-produced materials. But in terms of meeting an immediate and necessary global demand in the midst of COVID-19, this is a great step forward.

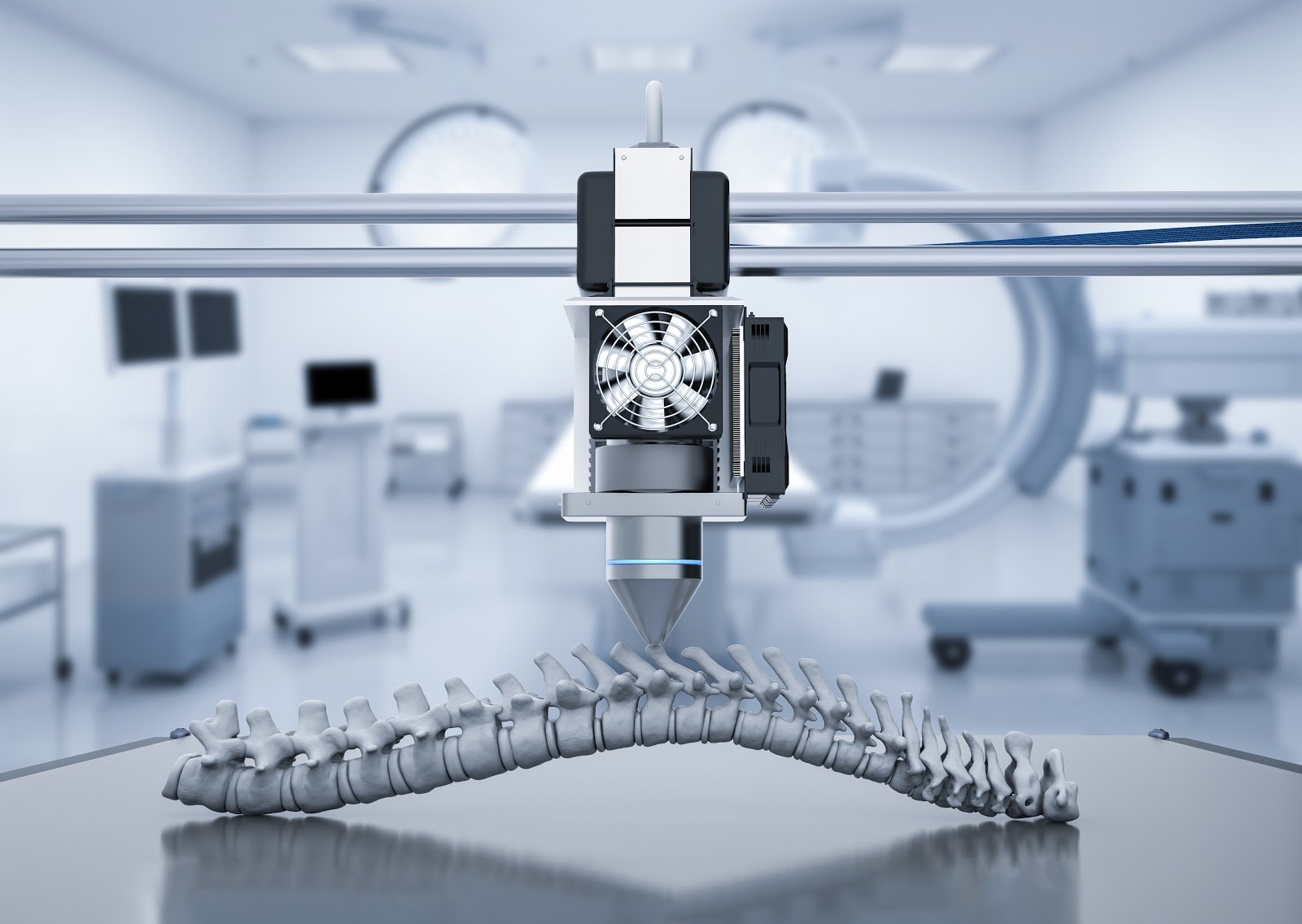

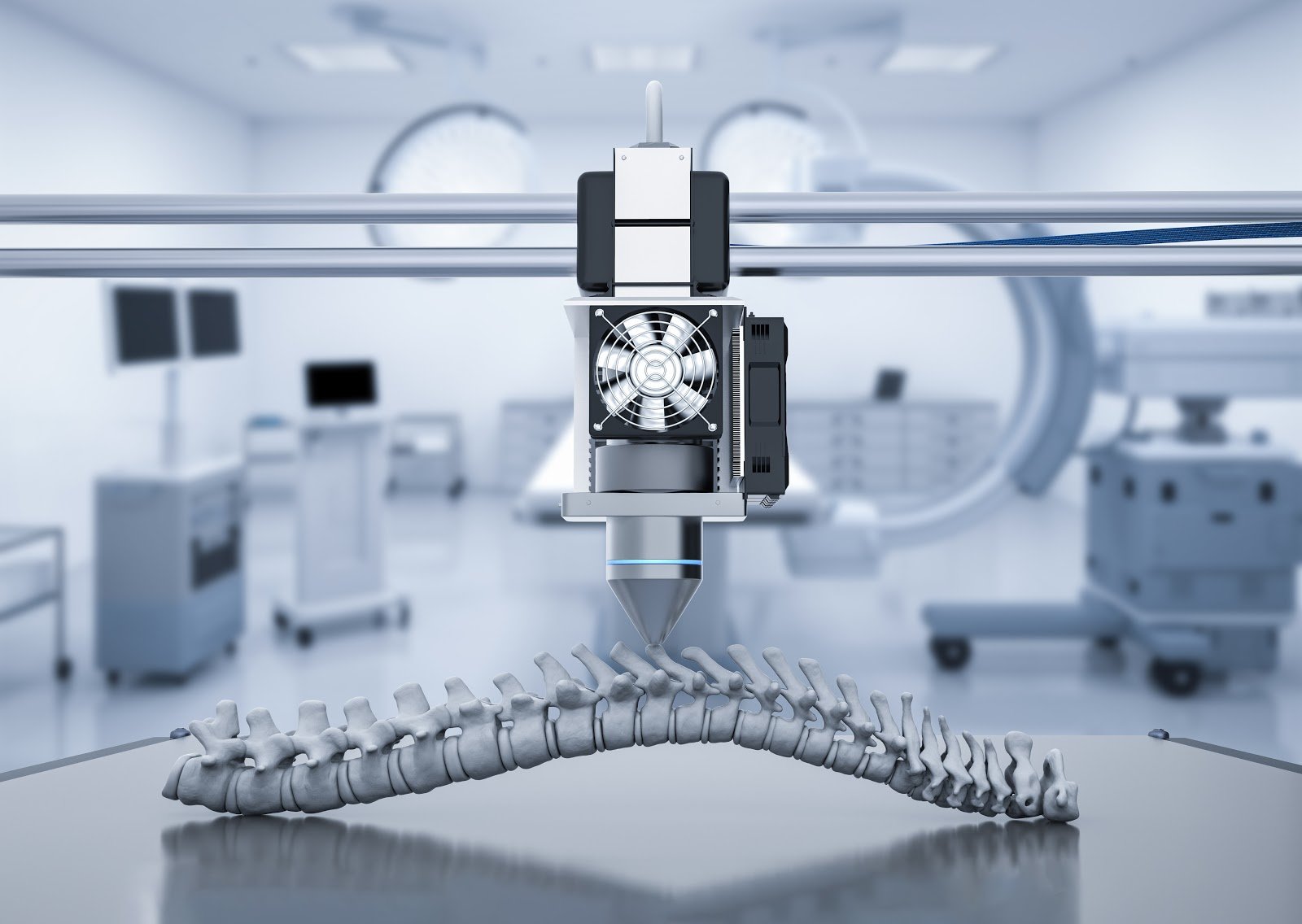

4. Medical Devices

Compared to the task of engineering complex cellular structures like hearts or bones, 3D printing medical tools sound like a breeze. And while there are plenty of challenges yet to overcome, researchers are making great strides in this area.

3D printed medical tools such as scalpel handles, clamps, and forceps are commonplace these days, but these are only the beginning. Just a few years ago, a team of students from the University of British Columbia won the 2014 Joel Burt award for their innovative surgical smoke evacuator, made possible with 3D printing.

Additionally, researchers from the University of Arizona were able to 3D print a completely sterile surgical retractor in only 90 minutes. This efficiency, combined with the low cost of 3D printed medical tools (as low as 1/10 of the cost of stainless steel equivalents) makes 3D printing an exciting area of study for decreasing the cost of surgical equipment and even expanding medical access to low-income and underprivileged areas worldwide.

5. Stem Cells

Stem cells are a promising area of study across numerous medical fields, and 3D printing is at the forefront. Due to their regenerative characteristics, labs across the country are bioprinting stem cells for various medical and surgical applications.

For example, consider recent research from Texas A&M University where scientists combined 3D drafting technology with bioprinting and stem cells to create personalized bone grafts. These grafts have the potential to facilitate fast bone regrowth and customized bone structures, all without the need for titanium implants. This area of study has the potential to revolutionize the way practitioners look at craniofacial implants and bone regeneration.

6. Pharmaceuticals

Another unique area of study for 3D printing is pharmaceuticals. Over the past few years, researchers have explored how 3D manufacturing could offer production advantages over traditionally-produced medicine. The first 3D printed pharmaceutical to be FDA-approved hit the market in 2015, with plenty of discussion and fanfare about the potential advantages of 3D manufactured drugs, which include:

- More consistency in large-scale medication production

- Innovative pill structures only producible through 3D technology

- Customized dosage release schedules for patients with unique needs

- Potential for on-site printing at local pharmacies

Beyond that, researchers report that these advancements could lead to even more futuristic applications down the road, including ingestible, Bluetooth-enabled electronic pills that sit in a patient’s stomach for up to a month. While the long-term applications of these technologies are still unclear, they’re an exciting, completely new type of 3D printing medical breakthrough.

The Future of 3D Printing Medical Advances

It’s hard to predict the future of such a fast-moving industry, but as 3D modeling software continues to advance alongside our understanding of human anatomy, it’s clear that the 3D medical printing market has nowhere to go but up. There’s a lot going on in the field, and we at Spatial will keep you informed of any advancements to 3D modeling worth knowing about.