In the 3D printing and additive manufacturing space, the two leading 3D printing technologies are Fused Deposition Modeling (FDM) and Stereolithography Apparatus (SLA).

Choosing between FDM and SLA ultimately depends on your objectives as each one offers specific advantages over the other. In this blog post, we’ll examine both so that you develop insights into how each one can factor into your 3D printing needs.

FDM: Fused Deposition Modeling

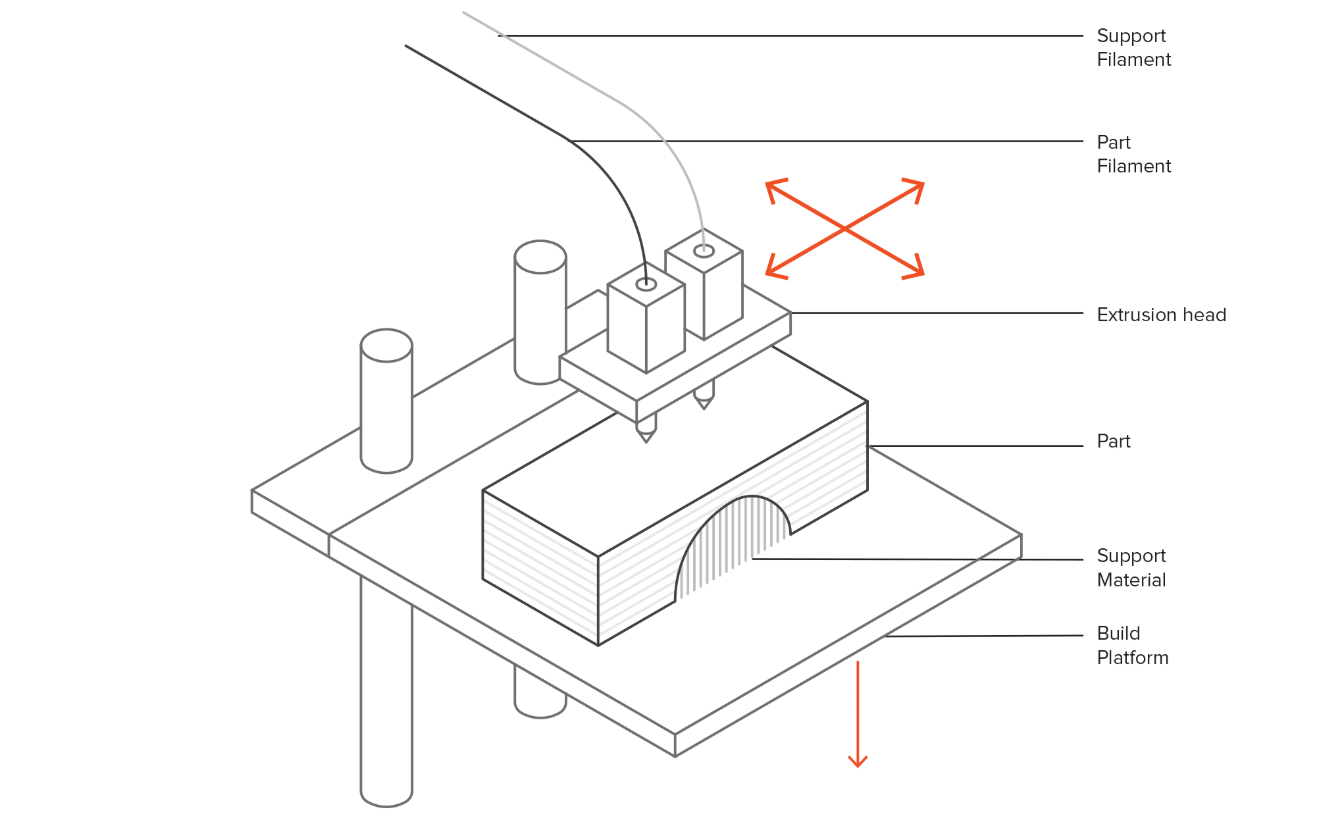

When using FDM 3D printers, you’re depositing the material (e.g., thermoplastics) in layers in order to produce a 3D object. The process starts with feeding the material through the printer’s hot extruder, which softens the material. In turn, the printer creates the 3D model layer by layer through an extrusion head; the model forms as each new layer bonds to the existing ones.

An FDM printer’s extrusion head can function in a 3-axis system wherein it can move along the X, Y, and Z directions. The extrusion head’s nozzle deposits the material in predefined locations in the printer’s internal space -- this information comes from its STL or OBJ CAD/CAM file.

In fact, accurate CAD/CAM information is critical because the FDM printer will refer to the file for instructions on how to “slice” each layer.

Basic Schematics of an FDM 3D Printer

Source: 3D Hubs

Advantages

Arguably one of the main benefits of FDM printers is that they made 3D printing accessible.

FDM materials generally have the lowest costs and barriers to entry. You can also choose from a diverse range of materials, including PLA, TPU, ABS filament, and composite blends made up of carbon fiber, ceramics, and other properties. You can also use many different colors.

The post-processing work of FDM printers is also simple in that you only have to remove excess plastic from the design. You can create a smooth surface using sandpaper.

Drawbacks

However, FDM-printed are also much simpler in design. FDM printers will have trouble creating high-resolution designs and intricate or complex structures/lattices.

Complex designs basically require “finer” slicing, and not every FDM printer is equipped for that fabrication level. But you can acquire those capabilities through industrial-scale FDM printers.

Why FDM 3D Printers?

Overall, FDM printers are a quick and cost-effective way of creating proof-of-concepts/mock-ups and simple prototypes. However, some industrial-scale models can manufacture complex parts, but these are generally much more costly than desktop 3D printers.

Learn How Renishaw is Using Spatial SDKs to Improve its

3D Printer Technology’s Production Reliability & Quality

SLA: Stereolithography Apparatus

Not only did SLA come before FDM, but SLA actually introduced the world to 3D printing from 1986. Today, SLA is the go-to 3D printing option for producing complex, high-quality parts.

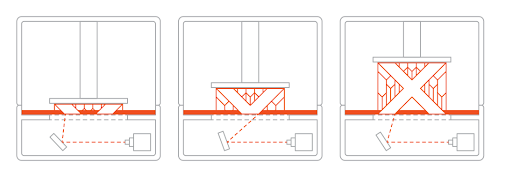

SLA printers create models using ‘curable photopolymer.’ This is basically liquid resin that the SLA printer cures layer-by-layer with an ultraviolent (UV) laser or light beam. SLA printers will generally produce the model from top to bottom, with the build platform underneath lifting the model upwards from the resin pool through the printing process.

Basic Schematics of an SLA Printer

Source: 3D Hubs

Source: 3D Hubs

Where FDM printers will deposit layers of the material atop of one another to create a model, an SLA printer will fire a UV light to a pool or “bath” of resin.

Advantages

SLA printers are capable of producing high-resolution objects, including those with very complex or intricate details, such as lattices and cavities. In turn, models produced by SLAs possess high durability and strength, especially intricate designs. In general, SLA-produced models provide a smoother finish as well.

Drawbacks

In general, SLA printers as well as the necessary resin material are costlier to procure than FDM printers and materials. Moreover, resins are proprietary, which can limit your flexibility in terms of how you intend to use a specific SLA printer model/make. Finally, SLA-produced models require more post-processing work than FDM due to resin residues.

Why SLA 3D Printers?

SLA is ideal for prototyping and, to an extent, mass producing complex designs. While cost and limited flexibility are constraints, FDM printers generally don’t match the details and quality given by SLA printers.

Choose Based on Your Requirements

Ultimately, FDM and SLA aren’t inherently better than the other. Your choice of 3D printer type depends on the actual use-case. If your goal is to produce simple designs at a lower cost, then FDM is the way forward. However, if you’re working with complex designs, then consider SLA.

In fact, you could potentially have a situation where you’re using both FDM and SLA so as to fulfill multiple, but different, objectives. Finally, selecting the “right” 3D printer is only one part

of the equation; you need to ensure the printer can properly read the design file as well!

Get More Competitive Insights About Additive Manufacturing:

- How the Best 3D InterOp Helps Reduce CAD File Errors in the Manufacturing Process

- How Poor 3D Data Translation Can Derail Project Timelines and Costs

- The Top 5 Ways Additive Manufacturing OEMs Can Decrease Costs

Just as developing 3D printers requires considerable expertise and resources in engineering and science, so does interpreting CAD/CAM files, especially across different formats.

In fact, FDM and SLA 3D printer manufacturers alike should focus on providing a best-in-class CAD/CAM interoperability, modeling, meshing and visualization experience. Otherwise, it won’t matter what type of 3D printer you use as the printer will struggle producing the model.

Spatial’s SDKs help ISVs and 3D printer manufacturers deliver first-in-class CAD/CAM format interoperability, 3D modeling, meshing, and visualization capabilities. Contact us today for an evaluation.