Over the past decade, 3D printing solutions have advanced at an unprecedented pace, paving the way for innovative solutions in industries ranging from the aerospace to automotive industries. One of the most significant advancements in this field is large-scale 3D printing, which enables the creation of objects on a massive scale.

With this technology, you can produce functional and intricate designs in a fully digitized process chain, opening up new possibilities for architecture, engineering, manufacturing, and more.

As large-scale 3D printing continues to evolve, it’s set to revolutionize the way we create, design, and innovate. Let’s take a look at the industry-changing nature of large-scale 3D printing and how your business can benefit.

What is Large-Scale 3D Printing?

Large-scale 3D printing is the process of creating three-dimensional objects on a significantly larger scale than traditional 3D printing techniques. It involves the use of large-scale 3D printers that are capable of producing objects that are several feet in size.

Large 3D printing is typically used where there is a need for the production of large, complex, and intricate parts. These often include industries such as aerospace, architecture, and automotive manufacturing.

3D printing for large scale enables the creation of parts that are more precise, durable, and efficient than those produced using traditional manufacturing methods. Additionally, it offers the advantage of faster production times and the ability to create intricate designs that would be impossible to achieve using other manufacturing techniques.

Efficient Additive Manufacturing Begins With Efficient Software

Help your users visualize, design, and better optimize with Spatial’s SDKs

Contact Us

What to Consider When Implementing Large-Scale 3D Printing

To print automotive parts and components for the aerospace sector, you need a larg e-scale 3D pr inter . And while the size is an important factor to consider when using a larg e format 3D pri nter , there are other factors that should also be taken into account, especially when 3D printing at scale. These include:

- Safety : You need to take safety considerations, such as making sure ventilation, personal protective equipment, and fire safety measures are used and being followed.

- Printer Costs : Ensuring a huge 3D printer can meet the specific requirements of an organization while being cost-effective is also essential. For example, your printer should be able to produce everything from functional prototypes to molds and patterns.

- The cost of a giant 3D printer can vary significantly depending on factors such as size (some run as large as one cubic meter).

- Material Costs: The type and quality of materials used impact overall production costs. Therefore, it’s important to choose high-quality materials that not only suit your applications but also provide quality and durability. For example, high-strength polymers are often used in manufacturing parts for the aerospace sector.

Source: 3DNatives

- Unibody Parts : In many cases, producers manufacture large objects using traditional assembly methods. However, such objects may have superior performance if they were produced as a single solid piece, a task that can be accomplished efficiently only with a big 3D printer .

- Design Freedom : Conventional manufacturing methods can make certain geometries impossible to create, such as complex lattice structures and internal channels. However, these features often support large objects like furniture, and the only way to achieve them is through the use of huge 3D printers .

- Printer Maintenance - Maintaining giant 3D printers on a regular basis is vital for ensuring their longevity and reliability. When implementing large-scale 3D printing, it's important to factor in the cost of maintenance, which includes parts and service.

98% of Power Users See 3D Printing as a Competitive Advantage

Using a 3D printer for large-scale production helps organizations accelerate product development while offering greater customization and flexibility.Make sure your 3D modeling software has the cutting-edge capabilities your customers demand

Learn More About Our SDKs

4 Examples of Large-Scale 3D Printing

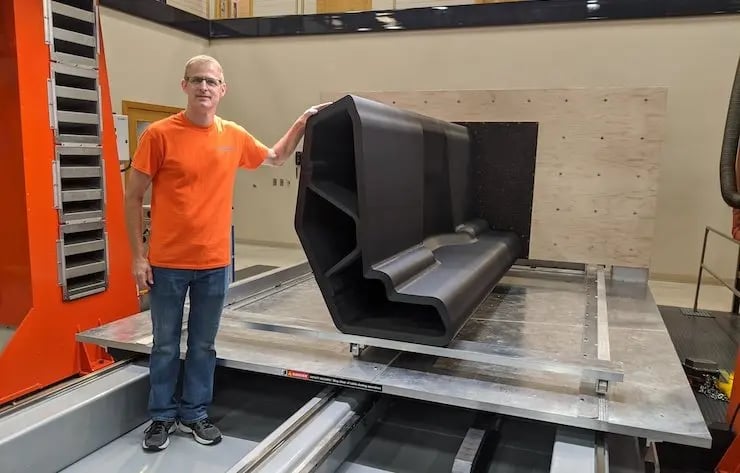

Large 3D printers have created a new wave of possibilities, from building bridges to printing entire cars, the applications of the technology are endless.

Here are a few examples of how large-scale 3D printing is being used today to transform industries and change the way we approach design and manufacturing.

- Furniture: Large-scale 3D printing furniture has skyrocketed in application, as using a 3D printer for furniture allows you to create intricate, lightweight designs that are both durable and functional.

- Architecture : A large 3D printer enables architects to create building and structure models with an incredible degree of precision, facilitating the visualization of designs and the ability to make changes before construction.

- Art and Sculpture : Artists use big 3 D printing technologies to create complex designs, intricate sculptures, and installations.

- Automotive Manufacturing : A large industrial 3D printer can be used to produce complex automotive components that are durable, lightweight, and tailored to specific models.

- Aerospace: Large-scale 3D printers allow for the manufacturing of aircraft parts built with high-strength composites.

- Maritime: The maritime sector is embracing the flexibility of 3D printing , using it for everything from large parts used in shipbuilding to at-sea maintenance.

Source: TCT Magazine

Types of Printers Used in Large-Scale 3D Printing

There are several types of 3D printers used in large-scale 3D printing , including:

- Stereolithography (SLA): A laser beam controlled by a computer gradually builds up the piece, thanks to a laser-reactive polymer

- Digital Light Processing (DLP): Similar in function to SLA, DLP instead uses projected light to set an entire layer

- Selective Laser Sintering (SLS): A laser melts and fuses powders, which are then stacked as the process continues

- Fused Deposition Modeling (FDM): A nozzle jets out polymeric fibers to manufacture a piece

While these printers vary in build volume , materials used, and post-processing , they are all capable of producing printed objects on a large scale. Additionally, there are specialized printers designed specifically for large-format 3D printing , like gantry-style printers, which can print large parts up to several meters in size.

Build your understanding of 3D printing, its uses, and how it can benefit your business with these blogs:

Cover All Your Large-Scale 3D Printing Software Needs with Spatial

3D printing workflows don’t have to be complex, frustrating, and riddled with errors. Give your end users a seamless experience and enable easy optimization of 3D printing workflows, at any scale, with Spatial’s 3D SDKs.

Trusted by 3D printing leaders for over 35 years, our SDKs empower you to visualize, manipulate, and export 3D models without missing a beat.

Contact us today to start optimizing your product development.