For those of you not familiar with waterjet machining, this is an industrial tool that is capable of cutting a variety of materials using an extremely high-pressure jet of water. A mixture of water with an abrasive substance is sometimes used as well. This method is used primarily when the materials being cut are sensitive to the high temperatures generated by other methods. Waterjets have the widest range of application of any machine tool, while maintaining high precision. There are virtually no limits to what waterjets can cut. So how does 3D come into play for waterjets?

With recent advances in control and motion technology, 5-axis waterjet cutting has become a reality. While 5-axis operations have been possible on abrasive waterjet machines for some time, the capability to process 3D parts such as tubes and pipes is relatively new. Where the normal axes on a water jet are named X (back/forth), Y(left/right) and Z (up/down), a 5-axis system will typically add an A axis (angle from perpendicular) and C axes (rotation around the Z-axis). This is where 3D modeling, visualization and data interoperability come into play. With specialized 3D software and 3D machining heads, complex shapes can be digitally modeled and produced. By integrating the specialized 3D software with the recent advances in 5-axis waterjet machines, machine tool venders are able to deliver flexibility, speed and accuracy like never before.

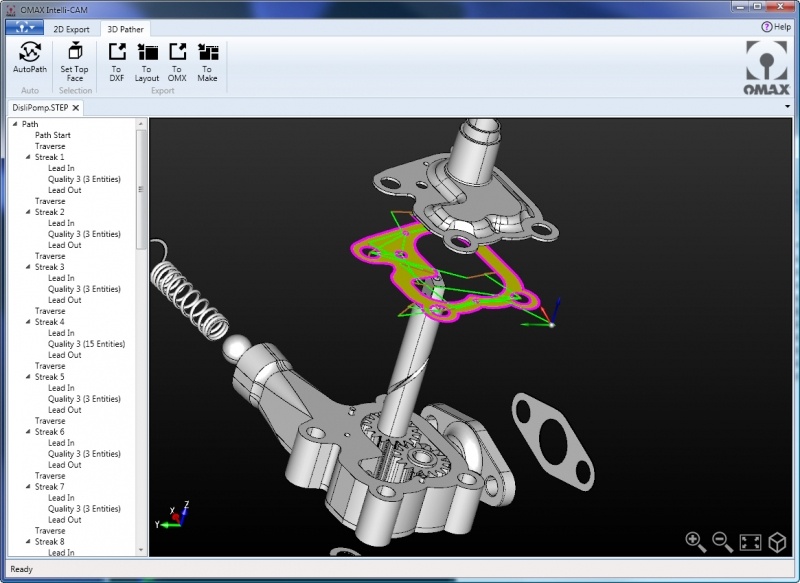

OMAX Corporation, a leading tool solutions provider of abrasive waterjet systems and Spatial Corp, the leading provider of 3D components aka Software Development Kits (SDKs), recently announced the co-development of a 3D tool pathing solution for waterjet machining. Spatial provides the middle-ware between OMAX’s CAD and the machine controller. The merging of these two leading technologies provides customers the ability to import practically any major 2D or 3D CAD model in the market today.

For OMAX customers doing 3D programming for 5-axis waterjet cutting, those operations are now greatly simplified. OMAX is delivering one of the easiest to use 5-axis CAM software solutions today with the help of Spatial’s 3D SDKs.

To learn more about Spatial’s 3D capabilities for other manufacturing and fabrication industries visit::

Manufacturing-Fabrication