Today's Manufacturing Workflow -- The Need for Speed

by Guest blogger Chris Skubic, Machine Research

Manufacturing is a prominent part of the global economy and is coming back to the US after decades of offshoring (see the Maker Movement) – with a noticeable focus on speed, speed, and more speed. 3D print shops are popping up all over the place and manufacturers are being asked for quick-turnaround quoting and prototyping. Companies like Proto Labs that focus on speed are seeing revenues and market value soar (Proto Labs’ most recent 10k), etc. There are many data points when addressing the need for speed in manufacturing these days. The faster you manufacture, the more profit you reap – and the more efficiently you need to operate.

Adapt, speed up, or get passed by those that do. It doesn’t matter if the project is a complex 5+-axis aerospace part, or how much post-processing needs to be done (for you 3D print shops) – these parts are expected to be turned quickly and most customers pay a premium for speed.

How do you speed up the Manufacturing Workflow?

Simply removing inefficiencies isn’t as easy as it sounds – some of the issues are culture-based, but there are many that are software-related and they should be fixable.

For example, going from RFQ to a quotation is cumbersome:

- You need an expensive seat of CAD software despite the fact that you’re not a designer and don’t use 85-90% of the functionality. Why? Well, you have to view the model. You’ll also likely have to translate that file type to jive with your CAM system. And…maybe the model itself needs healing/repair.

- You’ll also want to know if you’ve made a similar part in the past. How? Maybe thumbing through spare part bins. If you’re ambitious, you’re looking through your Windows- based file system trying to remember a part you made 18(?) months ago for (what customer was that?)… This kind of knowledge reuse could be a HUGE advantage in the “speed game” – it could help speed quoting, programming, manufacturing runtime, anticipate fixturing issues, and (for you 3D printer shops) part orientation and post-processing of supports. That’s a long list of benefits…but this is so difficult to do with your current software tools that it is almost never done. So, you re-create the wheel whenever you manufacture something new…

- A PLM or PDM system could definitely help. However, they can be expensive, entail dreaded “business process mapping and software deployment” time, and still not solve your workflow issues.

Again…How do you speed up the Manufacturing Workflow?

Machine Research was founded with a specific mission in mind – speed up the manufacturing workflow. We create software tools designed for manufacturers, not repackaged product design tools. Our tools enable manufacturers to mine and reuse knowledge of the past to quote and manufacture smarter, more efficiently, and more profitably going forward. We do this through a secure, cloud-based software service and offer monthly subscriptions for a fraction of what you could pay for other software/translator packages. And…yes…we’re ITAR-registered. Our initial service offerings focus on the front end of the manufacturing workflow – RFQ through quotation. We will expand our workflow tools downstream, but we had to start somewhere…the front made sense to us.

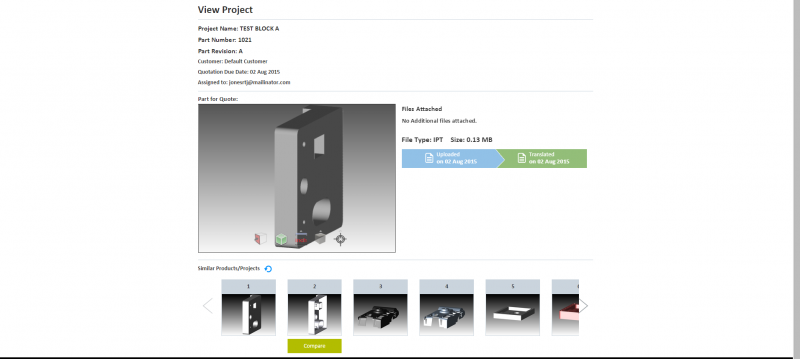

In conjunction with our friends at Spatial Corp, we developed our BASIC service offering that gives customers the ability to view, measure, collaborate, and translate from any 3D CAD file-type to any other without purchasing a CAD seat. We also created mobile apps – on both iOS/Apple and Android platforms – open, view, and measure any CAD file from mobile device.

The high-speed and reliability of the Spatial's 3D Interop™ Data Translation tool kit provide us with superior capabilities to read, translate and write a wide array of CAD formats – all completely integrated in our solutions.

Our PRO service provides customers the additional ability to manage projects, utilize our visual search engine to find legacy projects of similar geometry (and compare them), and standardize the quotation process across their organization. Our PRO service is specifically designed to enabling manufacturers to leverage their existing knowledge-base (quotes, manufacturing data, cost information, project profit margins, etc.) easily and quickly.

But don’t take our word for it, sign up for a free 30 day trial and find out yourself. In a manufacturing world where speed is becoming more and more important – companies can hardly afford to sit back on their heels. Adapt, speed up, or get passed by those that do. Don’t get passed by…we can help.