Due to different workflows, it is not uncommon to find companies collaborating with one another (e.g. a design/engineering firm and manufacturer) utilize different computer-aided design (CAD) suites. However, the risk with such processes is that both sides involved in the project will have difficulty reading non-native CAD files.

For example, a non-native CAD file could have inaccurate tessellation results, such as incorrect geometry and topology. However, the process of repairing such data is costly, not least in terms of the engineering man-hours required for the task, but via resulting delays to the entire design and production process as well.

Thus, the ability to deploy or offer applications that reduce - if not remove - the need for CAD file repair work is a key efficiency gain and, in turn, an opportunity for vendors supplying solutions to the design and manufacturing industries. Those opting to build solutions for non-native CAD file reading with accuracy and minimum risks use Dassault Systèmes Spatial’s 3D InterOp.

What is 3D InterOp?

3D InterOp is the reference software development kit (SDK) in data translation designed to enable applications to read imported (i.e. non-native) 3D data as normally as a native CAD data file. Software built with 3D InterOp preserves the non-native CAD file’s design intent.

3D InterOp supports all industry-leading 3D data exchange formats, including 3D ACIS Modeler, CGM Core Modeler, and Parasolid. By using this SDK, developers have the means to guarantee that their applications can import and export CAD files between siloed teams - including those in other companies - without being hampered by frequent data-loss and wrong tessellation results.

In addition to delivering the original 3D CAD file’s design intent, 3D InterOp leverages a range of methods - including multithreading, direct translation, and improved algorithms - to deliver results as quickly and reliably as possible for your applications.

Applications leveraging 3D InterOp flow across a part’s downstream channel, i.e. from the original designer through to manufacturers, their material vendors and other stakeholders tied to manufacturing the part. In other words, you have a large addressable market.

Consistent, Accurate & Reliable Translation

3D InterOp drawson Dassault Systèmes Spatial's deep cadre of 3D modeling experts. Our experts have extensive experience in the calculus necessary for fixing an imported CAD file’s geometry. We handle the CAD file repair element so that you can focus on perfecting your application’s user experience, differentiating features and other aspects while retaining credible data-translation capabilities.

3D CAD data is essential for Model-based design (MBD) wherein the CAD file is the sole source-authority for a part’s design, materials and other attributes necessary for its production. MBDis increasingly becoming a reality in the engineering, design and manufacturing domains because it leads to fewer errors, reduces the cost of design iterations and provides a common data environment for communication across departments and businesses. As such, an application leveraging 3D InterOp can see adoption with a diverse line-up of clients.

In fact, interoperability is also important from a cross-functional standpoint. For example, one’s marketing, legal and/or operations departments may need access to the CAD file (and original design intent) for their respective tasks. Equipping non-design/engineering departments with a full-featured CAD license could be cost-prohibitive, which makes having an application capable of reading different CAD formats advantageous.

Regarding manufacturers, 3D InterOp enables them to readily view the part’s dimensions and tolerances. We ensure that your applications provide manufacturers the capacity to determine accurate inputs for analysis and processing (such as correctly inserting commands for machining systems), thus preventing manual file repair work and damage to facilities.

Continually Evolving

Dassault Systèmes Spatial is committed to continually evolving 3D InterOp through regular performance and feature updates, thus ensuring that your application or end-user solutions are free of stagnation. Rather, Dassault Systèmes Spatial works to ensure that your solutions remain relevant in the industry by constantly meeting the needs of the market, be it new formats, workflows or industry-wide shifts.

For example, the SDK offers automation options for certain capabilities, with developers given the opportunity to decide what aspects to automate and what features to make available to both users and administrators alike.

Reliable & Developer-Centric

3D InterOp is designed and maintained with developers at the forefront. In addition to Dassault Systèmes Spatia’s robust in-house testing of the SDK, 3D InterOp also draws on the experience of millions of end users operating globally through industry-leading applications.

In addition, Spatial - by virtue of being owned by the same parent company, Dassault Systèmes, - is also able to draw on SOLIDWORKS and CATIA libraries, guaranteeing that 3D InterOp can read industry-leading CAD file formats used in a range of complex industries, such as aerospace.

Software is Integral to High-Quality Manufacturing

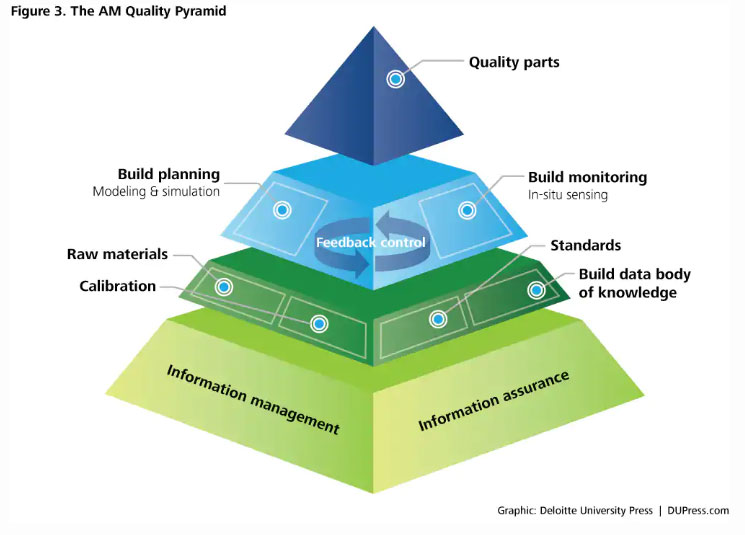

Industry shifts, such as the growing adoption of additive manufacturing, are pushing design and manufacturing teams alike to rely on digital assets - such as 3D CAD files - for their processes.

In fact, the industry’s ability to produce a high-quality and cost-effective part is contingent on not just the design, but whether the metadata - i.e. Product and Manufacturing Information (PMI) - is also included. This PMI includes the part’s surface geometry and resources (e.g. metals).

When the correct PMI is conveyed, manufacturers can properly calibrate their machines and correctly order materials from their vendors, thus ensuring that the part is built according to the designer’s specifications and, in turn, controlling costs (by removing delays, wrongly produced parts and manual file repair work) throughout the chain.

When the correct PMI is conveyed, manufacturers can properly calibrate their machines and correctly order materials from their vendors, thus ensuring that the part is built according to the designer’s specifications and, in turn, controlling costs (by removing delays, wrongly produced parts and manual file repair work) throughout the chain.

Solutions that fulfil the 3D data translation requirements to empower cross-functional teams to access the necessary metadata - and to do it cost-effectively - will be at the forefront. You can accelerate your entry in this market through 3D InterOp.

Request an evaluation of 3D InterOp today to examine how the SDK will markedly enhance and differentiate your applications.

.jpg?width=450&name=Application%20Lifecycle%20Management%20(1).jpg)