In a past blog, The Impact of Model-Based Definition (MBD) on 3D Modeling and Manufacturing, we discussed the growing role of MBD. To recap: although 3D modeling has been the standard in design for decades, many manufacturers still rely heavily on 2D drawings when communicating with suppliers. MBD enables the next step in CAD evolution where the 3D model becomes the means of communicating manufacturing data and specifications (product and manufacturing information or PMI).

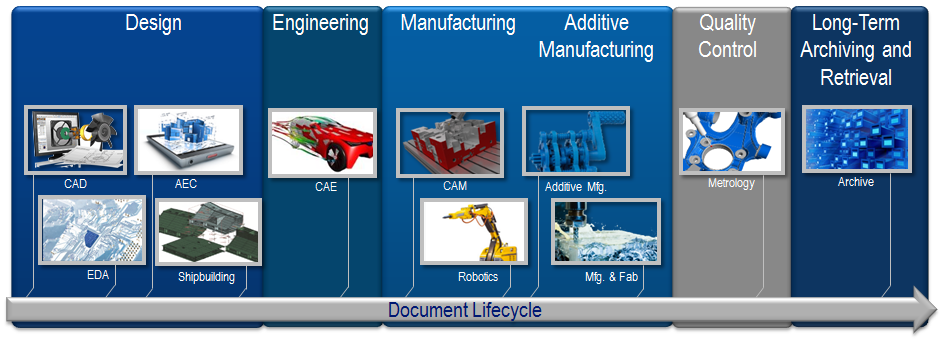

But MBD often only addresses the part of the design phase of the product. There are still the issues of how to manage, store, and communicate the resulting model data through the rest of the process as well as to all of the stakeholders: suppliers, subcontractors, customers, regulatory agencies, etc. STEP Application Protocol 242, Managed Model-Based 3D Engineering, (AP 242) attempts to address these issues by defining a larger framework.

The Goal of STEP AP 242

Any discussion about a standard typically devolves into an array of three-letter acronyms (TLAs), causing you to rush to Wikipedia to try and sort it all out. AP 242 is no different — the standard addresses the concerns of MBD, PMI, PDM, PLM, LTA, etc. Boiling this alphabet soup down: the goal of this emerging standard is to ensure interoperability between systems by standardizing on the type and form of data needed to manage a system throughout its lifecycle (known as product lifecycle management, or PLM). The important aspects of PLM in this context are:

- MBD, or the front-end design data

- Product data management (PDM), or the configuration control needed for a hardware system (similar to version control for software)

- Long-term archiving (LTA) of model data to ensure that data on a fielded system is accessible 20 years from now

The Genesis of STEP AP 242

The automotive and defense/aerospace industries are using parallel standards to address CAD interoperability, as well PDM: AP 214 and AP 203. Because the overlap in supplier bases (hardware and software) and similarities in the complexities of the end systems, there is a desire on the part of both industries to work on a combined standard, in part for the sake of efficiency.

While these two standards have similar goals and functions, their structures differ sufficiently so that a new merged standard is needed (versus one superseding the other). AP 242 merges these two standards and extends them to provide a more complete set of data to support the full lifecycle. Specifically, the new standard will add new functionality not currently found the earlier standards:

- 3D geometric dimensioning and tolerancing extended to include semantic data

- 3D shape quality

- 3D parametric/geometric constraints design

- 3D kinematics assembly

- Sustainability information

- Access and digital rights management (DRM)

- Software/mechatronics

- 3D electrical harness

- 3D piping

Benefits of AP 242

The backers of the standard describe a number of use cases that AP 242 is designed to address:

- Expansion of MBD throughout the supply chain and product lifecycle, allowing the 3D model to be the only specification.

- Improved integration with the supplier base, allowing for the sharing of the product definition based on a single standard.

- Engineering visualization by way of a lightweight format to allow for lower-cost viewers. This focus will allow many more users involved in the lifecycle to access the 3D model directly.

- Long-term archiving is a major concern for industries that require documentation be available long after the design is complete.

STEP AP 242 and Spatial

STEP AP 242 is an emerging standard, one that Spatial is committed to supporting. We have a long history of both supporting and enabling interoperability — much of the data specified in AP 242 is already translated by 3D InterOP directly from the CAD file formats — adding AP 242 support will further enhance our capabilities. With our upcoming 2017.1.0 release at the end of July, Spatial will be adding our first capabilities to read and write AP 242 files.

.jpeg?width=450&name=AdobeStock_289023609%20(2).jpeg)

.jpg?width=450&name=Application%20Lifecycle%20Management%20(1).jpg)