The beginning of the year is a time for planning, both in our personal lives, as well as professional. It is no different here at Spatial.

We are excited to begin sharing our plans and goals for the future with our customers. One of our focus areas this year is model-based definition, or MBD.

What is Model-Based Definition (MBD)?

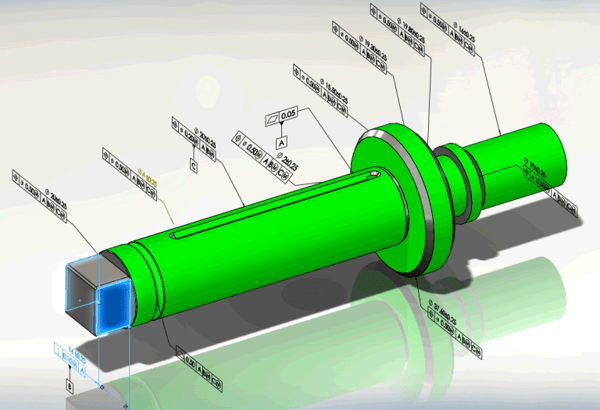

For the uninitiated, MBD takes the final step in CAD evolution where the 3D model becomes the means of communicating manufacturing data and specifications (product and manufacturing information or PMI).

Although 3D modeling has been the standard in design for decades, many manufacturers still rely heavily on 2D drawings when communicating with suppliers.

But MBD, a trend that started in aeronautics. is now expanding to other industries as they see the benefits to quality, cost, and time to market.

Why is MBD Important?

We humans think, create, and exist in a 3D world.

2D representations, or drawings, have been used to communicate design intent for centuries.

While effective, drawings always force anyone working from the drawing to reconstruct a 3D view, often in their mind, piecing together various 2D views of the same object.

This translation can often lead to errors and delays. Keeping data in the 3D realm brings many benefits to industry.

See Why High Quality 3D Data Translation is Vital for Manufacturing:

- The Importance of Quality 3D Data Translation in Manufacturing

- 7 Common Manufacturing Problems Caused by File Translation Errors

Minimize Error When Sending 3D Models (with PMI)

Clearly, MBD eliminates the error-prone process of converting 3D data to 2D drawings and specifications, but the impact on quality is greater than it might seem.

With the rise of 3D CAD and advanced manufacturing, many vendors will take 2D drawings from their customer to reconstruct a 3D model.

However, this adds another chance for error and misinterpretation as data is manually re-entered. Thus, any engineering change order (ECO) to the original design must ripple through the same time-consuming conversion process.

With MBD, the 3D model is combined with PMI data — the model becomes the specification.

Rather than communicate with 2D drawings, the 3D model with PMI is sent, becoming available almost immediately to the vendor. Any changes to the original design are easily communicated across the entire supply chain quickly and accurately.

Simplify Collaboration Between Designers and Manufacturers

One of the major benefits to MBD is the ease of collaboration.

Design teams can work easily with teams on the manufacturing floor; subcontractors can communicate issues with their customers in real time.

MBD also allows companies to communicate with their customers, vetting design changes and options easily, even allowing customers to integrate a subsystem into a larger project.

What Does MBD Mean For Solution Providers?

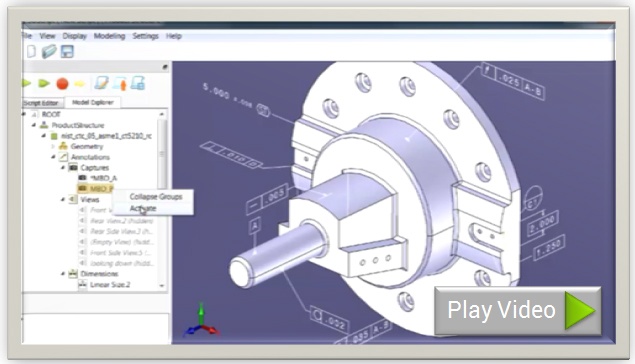

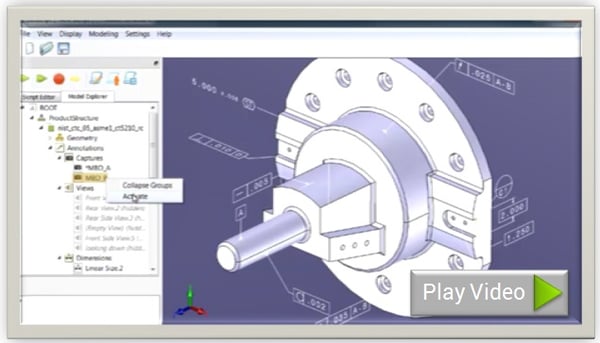

From a software solution perspective, MBD places two huge requirements on the modeling engines and the resulting data: interoperability and visualization.

Interoperability

If the 3D model now becomes the engineering specification, it is crucial that the model data can be communicated to others’ entities within the supply chain, but no one software company can own 100% of the market or provide all solutions.

As a result, entities up and down the supply chain will often have differing toolsets.

The ability to accurately translate model data from a wide-range of sources is key, allowing everyone in the supply chain access to the same data.

The other value to interoperability comes from combining data from one source with data from another source, allowing the 3D model to be the entire specification—the basis for collaboration.

The desire within the industry for interoperability drives collaboration between software vendors and the push towards standards over proprietary formats.

Visualization

Because with MBD the 3D model is now the specification, a wider range of teams need to be able to view and interact with that data.

Component suppliers need access to the model data to manufacture piece parts, but don’t need all the capabilities of a sophisticated CAD system.

Model data is not just for manufacturing. For example, marketing teams need to see what the end product looks like for market validation and promotion. These needs drive the requirement to be able to visualize the model in a multitude of environments and on a variety of platforms.

Looking Forward

So what are the focus areas for solution providers in the future?

The industry will work on better interoperability by improving support for competitor formats.

In addition, manufacturing and engineering data support will be improved by adding better hole data, cosmetic threads and thread names, as well as support for user-defined attributes (UDA) in models.

Improving interoperability among vendors also means better adoption of industry standards. Look for broader adoption of STEP AP 242 (ISO 10303-242), Managed Model-Based 3D Engineering, among software providers.

You might also like:

- Leverage 3D Visualization to Improve Your Manufacturing Processes

- How Poor 3D Data Translation Can Derail Project Timelines and Costs

On visualization, look for better support for photorealistic visualization through the use of voxel data. Photorealism is not only useful from a marketing perspective when communicating with customers, but also for collaborating with non-engineering groups within a company and the supply chain.

Mobile access to data is expected today.

A product team is often globally distributed, so access to data is needed at many locations at once. Data is needed on the manufacturing floor or at a customer jobsite for real-time collaboration. The industry will offer better cloud and mobile visualization solutions to enable wherever and whenever collaboration.

You can look forward to us continuing to enhance our support for model-based definition and engineering. To see how our software development kits (SDK) support CAD file interoperability and 3D visualization, contact us today.

.png?width=900&name=pasted%20image%200%20(1).png)

.jpeg?width=450&name=AdobeStock_289023609%20(2).jpeg)

.jpg?width=450&name=Application%20Lifecycle%20Management%20(1).jpg)