Rapid prototyping is becoming a go-to product development solution for manufacturers and innovators alike. Subtractive rapid prototyping is empowering businesses to make products with stronger parts and streamline time to market. This rapidly evolving technology heavily leverages 3D printing technology and automated CNC instrumentation.

Subtractive rapid prototyping allows companies to slash years off product development times while significantly lowering development and manufacturing costs within several industries. This is likely why the rapid prototyping market is expected to grow at an impressive CAGR rate of 14.9% between 2022 - 2031.

We’ll take a look at subtractive rapid prototyping, explain how it differs from additive prototyping processes, and explore scenarios for its use.

What is Subtractive Rapid Prototyping?

Subtractive rapid prototyping (SRP) is used by manufacturers, research engineers, and production planners to quickly create physical samples for review and testing.

SRP renders prototypes by removing material from a solid piece of metal, wood, or another physical medium. For example, this is not dissimilar to hand carving a work of art from stone or milling a banister spindle from a piece of wood.

However, in subtractive rapid prototyping, design software and CNC machine technology are leveraged to render prototypes instead of traditional, less automated methods. It also decreases prototype production turnaround times while increasing precision and accuracy.

Empower Your Users to Decrease Time-to-Market

Optimize product development with advanced SDKs.

Contact Us

Examples of the Subtractive Process in Rapid Prototyping

Industries that rely on subtractive rapid prototyping processes include:

- Automotive manufacturers: SRP allows for quick design involving several iterations and functional testing—ideal when you’re designing and testing engine components or vehicle parts.

- Medical device manufacturers: Orthopedic implants, surgical tools, and dental prosthetics can be developed and tested using SRP, including optimization for functionality and each patient's fit.

- Molds and dies: Automated subtractive techniques makes the production of injection molds, blow molds, and die-casting molds easier.

What is the Rapid Prototyping Subtractive Process?

There are three primary segments to any industrial SRP process.

First, an engineer or product designer uses computer-aided design (CAD) software to develop a 3D digital model of the desired prototype.

Next, that information goes to a CNC machine equipped with the right software, machining capability, and material substrate.

Finally, using the design specifications as its guide, the CNC machine will quickly and accurately hone the prototype to completion. Subtractive techniques may include carving, milling, laser-cutting, grinding, drilling, or other machining methods.

How Subtractive Rapid Prototyping Differs from Additive Manufacturing Methods

Subtractive and additive manufacturing processes are valuable techniques that save companies time and money while increasing the quality and efficacy of prototypes they're used to generate.

This is where the similarities between these two processes end.

As we learned earlier, in subtractive rapid prototyping, you begin with a solid piece of material. This could be a metal alloy, plexiglass, lucite, polypropylene, wood, or other material. From there, a machine expertly reduces that material until it completes your design.

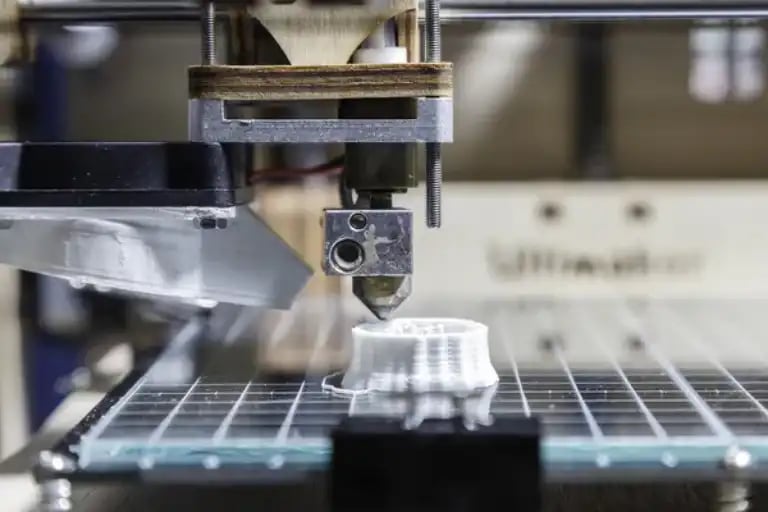

However, in additive rapid prototyping, the opposite process happens. Instead of whittling and milling material to the perfect form, you build the prototype from scratch using advanced 3D printing processes.

Additionally, there are different additive manufacturing solutions, including selective laser sintering (SLS), stereolithography (SLA), and more.

Key Differences Between Additive and Subtractive Rapid Prototyping

|

Additive Rapid Prototyping |

Subtractive Rapid Prototyping |

|

|

Creation Method |

|

|

|

Material Selection |

|

|

|

Specification Complexity |

|

|

|

Surface Finish |

|

|

|

Costs |

|

|

When to Use Subtractive Rapid Prototyping

When comparing the different capabilities and limitations of additive and subtractive manufacturing, it's easy to see that each is ideally suited for different manufacturing scenarios.

Some of the best (and almost most common) times you should use subtractive process rapid prototyping include the following:

- To meet high precision machining requirements: Subtractive manufacturing can meet tight specification tolerances and execute high-precision measurements critical in specific industries such as aerospace or medical device production.

- When surface finish quality matters: When developing a prototype where surface finish is vital to its performance and stability, such as high-pressure engine parts, subtractive rapid prototyping is the superior solution.

- For testing in rugged environments: Prototypes tested in harsh environments are best rendered with the final product material, using subtractive manufacturing techniques.

- In late stages of product development: Late-stage prototype iterations often shift from an additive manufacturing approach to a subtractive process to test the model using material meant for use in the final product.

When to Use Additive Manufacturing

Additive manufacturing technologies offer unique advantages and capabilities to product development teams that subtractive manufacturing solutions can often not meet.

Five examples of when additive manufacturing is preferential for rapid prototyping activities include:

- When complex design geometries are required: Additive manufacturing relies on advanced 3D printing technology that accurately translates complex geometries into physical models using detailed accuracy.

- For fast research and development: Additive manufacturing is a quick and cost-effective form of product creation that is ideally suited for early-stage prototypes and for evaluating multiple product variables in a relatively short time frame.

Learn how additive manufacturing is making waves with these blogs:

- Small batch design and manufacturing: Teams can quickly produce limited edition product launches, patient-customized devices, and custom designs with additive manufacturing solutions. They also upend the need for extensive operational and infrastructure investments.

- When mass matters: Keeping a product's mass low by choosing additive manufacturing processes and materials helps control transportation costs or allows engineers to meet specific aerospace and automaker industry weight standards.

- When managing material costs: Material cost and processing waste reduction are inherent to all additive manufacturing solutions as they efficiently create physical items without excessive waste.

Take Your Subtractive Rapid Prototyping Capabilities to the Next Level

Subtractive rapid prototyping aids the creation of robust, tested, and more impactful products and manufacturing solutions.

At Spatial, our 3D SDKs are helping teams harness this new potential while reducing prototyping costs and design times. SDKs for meshing and modeling guarantee high-fidelity simulations, and reduce the risk of potentially costly human error—all while preserving model accuracy.

Contact us today to learn how we can help increase modeling accuracies and streamline CAD workflows.